Description

Industrial gear mineral oil for use in gear transmissions of modern imported and domestic equipment requiring the use of high-quality oils with increased anti-wear and extreme pressure EP (Extreme Pressure) properties.

Product properties:

- Has excellent anti-wear and extreme pressure properties due to the use of a modern anti-wear anti-friction additive package. Reduces the likelihood of scoring, pitting, fretting corrosion, sulfur corrosion and at the same time reduces energy consumption. Reduces the running-in period;

- Has excellent antioxidant properties, anti-foam and demulsifying characteristics, which allows to increase the oil change interval and increase the service life of the equipment even in conditions of possible water ingress. Reduces repair and maintenance costs;

- Effectively combats all types of corrosion of ferrous and non-ferrous alloys and is absolutely compatible with all types of seals and gaskets;

- Due to good low-temperature properties, it maintains its operability at low ambient temperatures (down to -28 °C);

- Due to its versatility, it allows unifying the range of gear oils used at the enterprise;

- Improves the condition of the surface even if it is damaged, has a micro-smoothing effect.

Recommended for closed industrial gear wheels (reducers), lubricated by circulation or splashing (oil mist), especially where there are high loads and temperatures, vibrations, high speeds and sliding friction. It can be used for lubricating various mechanisms and individual components operating under high loads: all types of gear transmissions (including worm and screw), couplings and all types of rolling and plain bearings, etc., where the performance level of DIN 51517 Part 3 CLP and viscosity of ISO VG 220 are required.

Recommendation

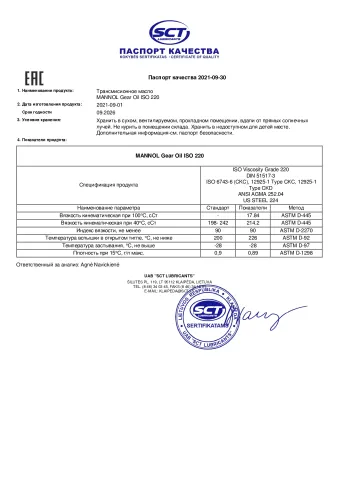

ISO Viscosity Grade 220

DIN 51517-3

ISO 6743-6 (CKC)

ISO 12925-1 Type CKC

SO 12925-1 Type CKD

ANSI AGMA 252.04

US STEEL 224